¶ Router Bits!

¶ Naming A Router Bit

[Size] [Number& Type of Flutes] [End Geometry] … [extra information]

EX:

- ¼” 4-Flute Spiral End Mill

- ½” 2-Flute Straight Ball Nose

- ¾” 2-Flute V-Bit with a ¼” Shank

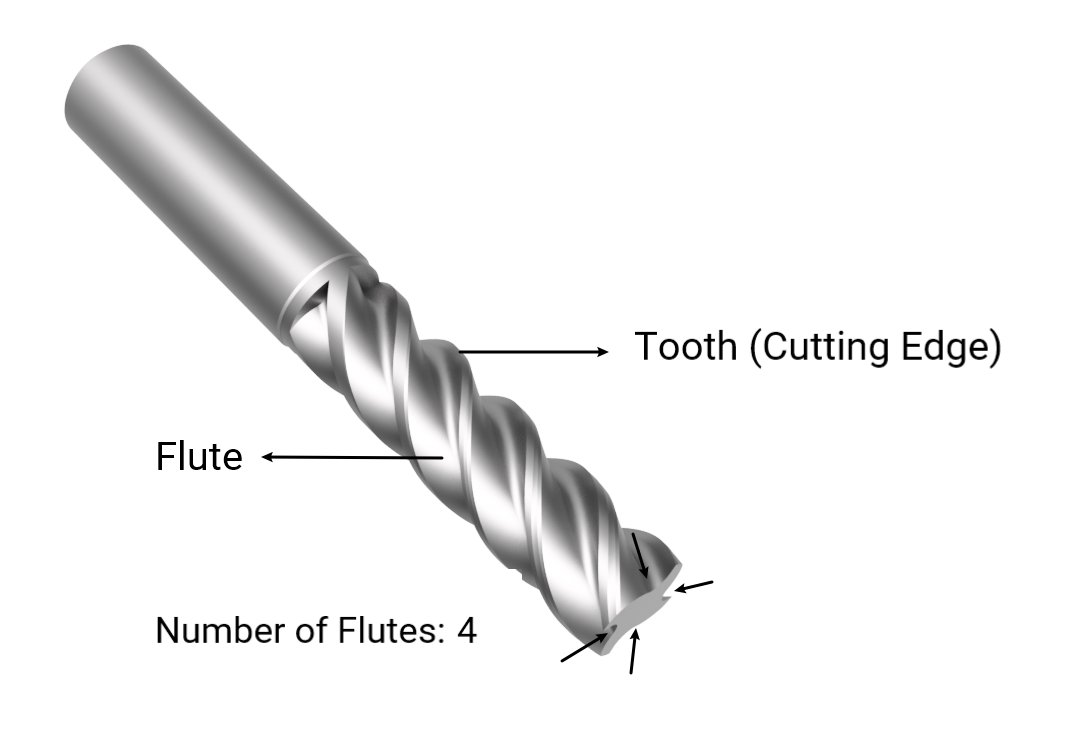

¶ Flutes/Teeth

Teeth refer to the cutting edges, and flutes are the grooves formed between teeth. As the bit rotates, teeth are responsible for cutting materials off, while flutes help evacuate the chips from the workpiece. Though not to be taken as the same thing, these two terms are usually interchangeable since they are always identical in number.

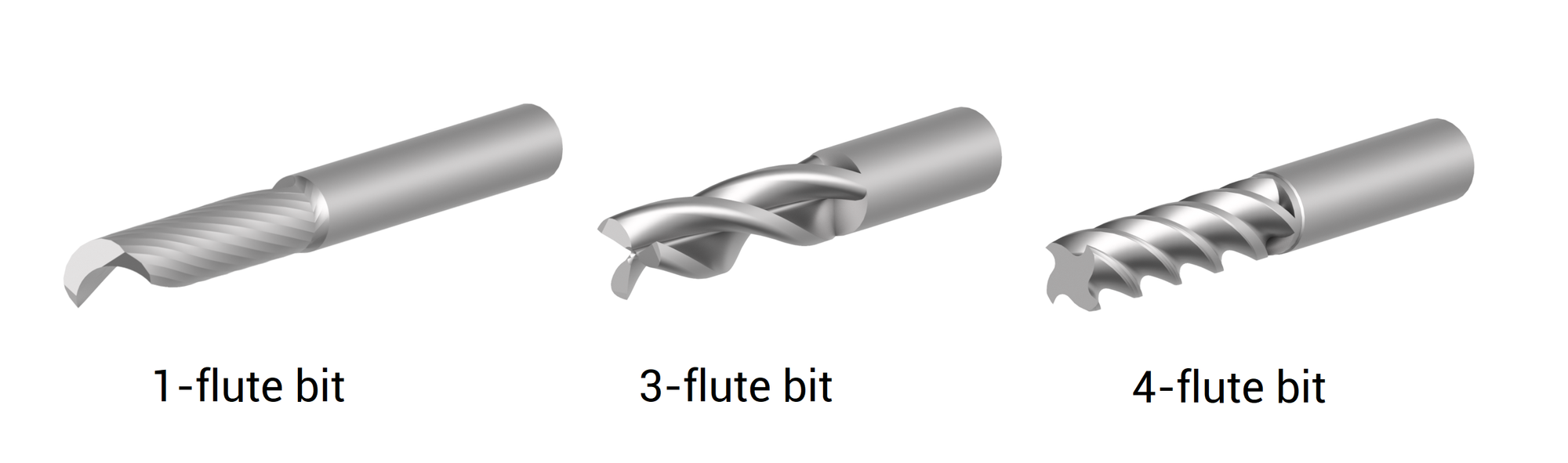

¶ Number of Flutes

More Flutes: Stronger, Better Surface Finish

Less Flutes: More Material Removal, Faster

Flutes serve as the passage for chips to evacuate, and chip clearance is the amount of space that a single flute takes up. When the number of flutes increases, chip clearance gets smaller, hence the more difficult for the chips to be evacuated. If you can't get the chips out, the heat produced during cutting will build up, eventually destroy the bit and even lead to burning.

¶ Type of Flutes

A straight flute is parallel to the shank of the bit, striking the surface of the material perpendicular to the rotation direction. Straight bits are stronger than spiral bits and can be used at higher speeds. On the other hand, they produce less smooth surface finish on the workpiece since such design brings more chatter. They are commonly used for slotting and cutting straight contours.

A spiral flute goes along the shank of the bit spirally, staying in constant contact with the material surface. Such design allows less chatter and leaves the finished surface smoother, making these kinds of bits ideal for trimming surfaces. However, spiral bits are weaker when held against straight ones and cannot cut too deep into the material or work at very high speeds.

¶ Geometries

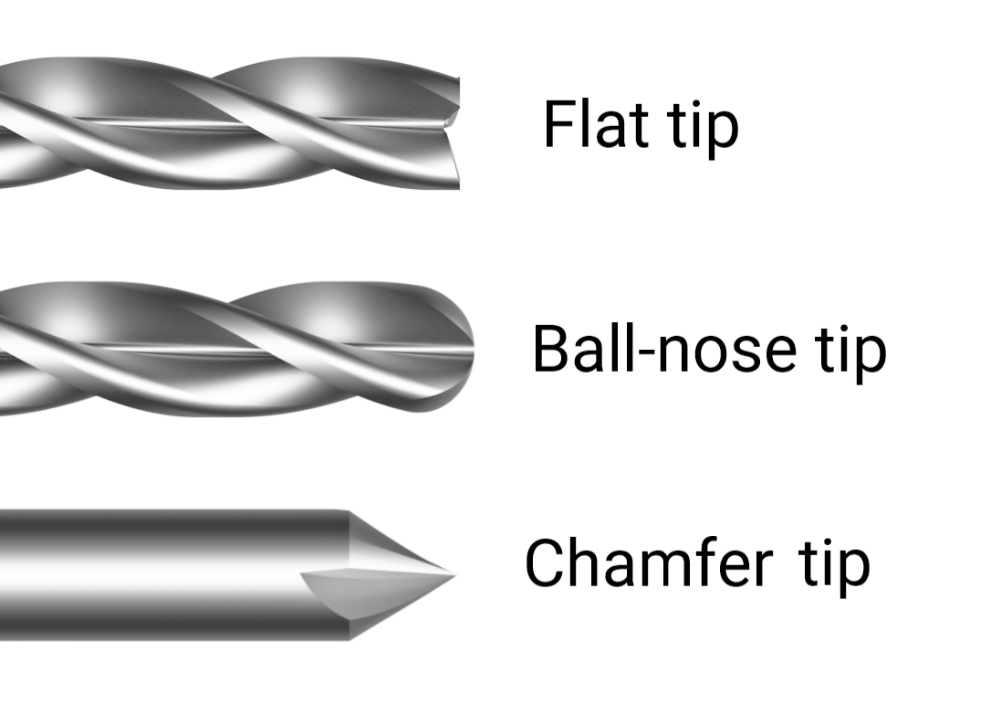

¶ Shape of Tip

Router bits come in a variety of tips, each creating different shapes of cuts as they engage with the material. Some of the most common types you will find are flat, ball-nose, and chamfer.

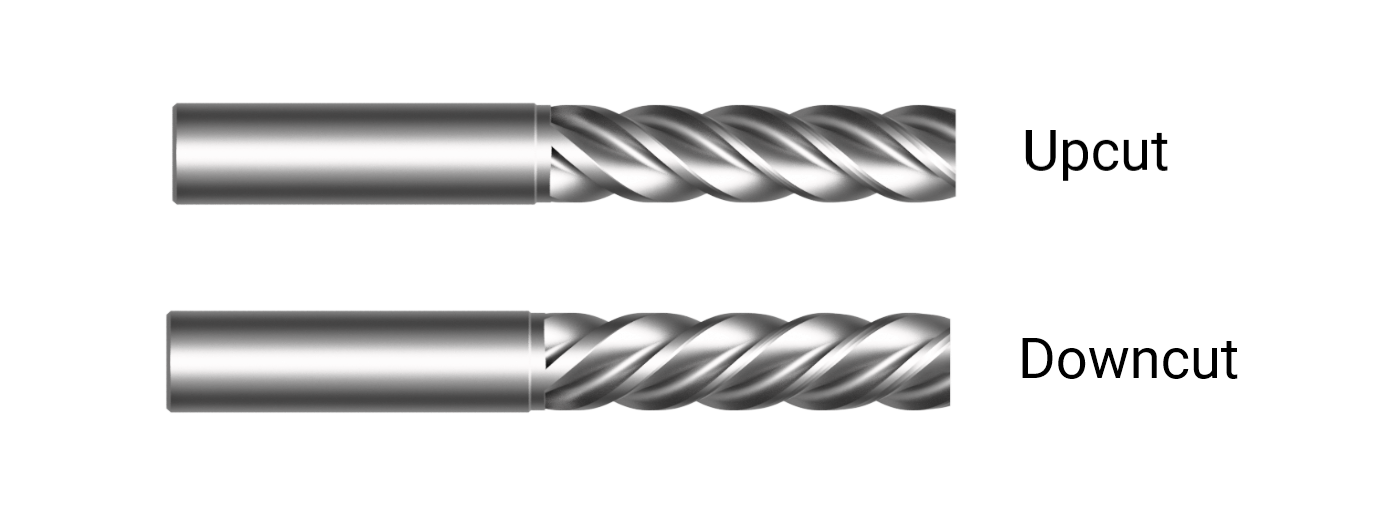

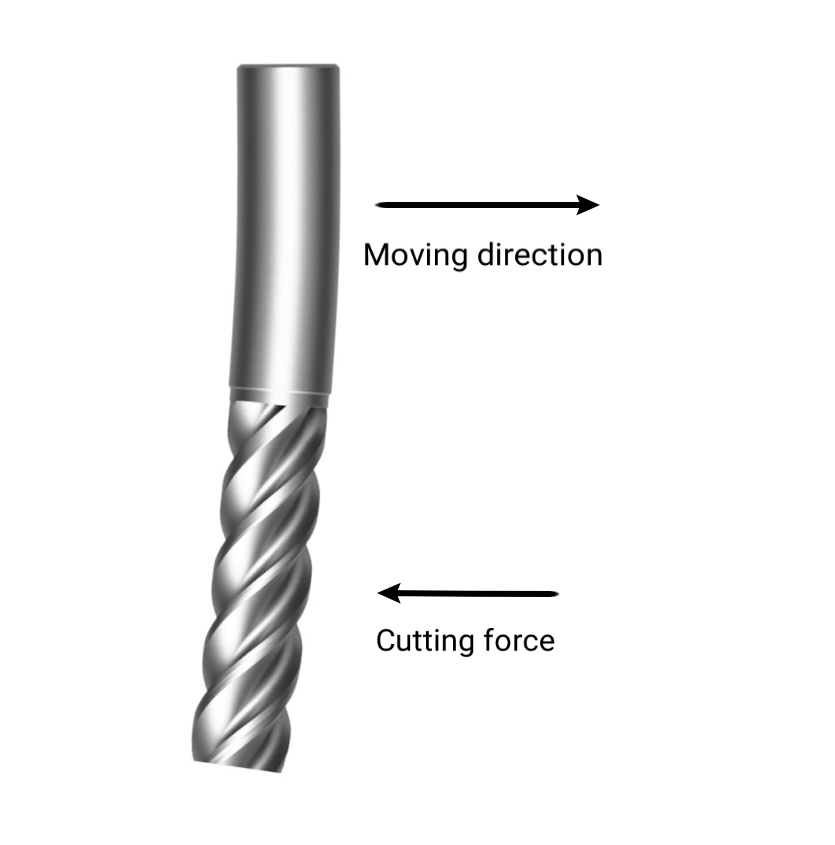

Upcut vs. Downcut

Spiral flutes can be further divided into two categories: upcut and downcut. The differences between the two types of spirals are crucial because they determine the direction in which chips are evacuated.

The spiral flutes of an upcut bit wrap around the body of the bit clockwise, pulling chips away from the workpiece being cut. An upcut bit tends to leave a rough surface finish on the top of the workpiece and a smooth surface on the bottom.

A spiral downcut bit, however, pushes chips down as it's cutting, with the flutes wrapping around the bit counterclockwise. Conversely, a downcut bit leaves a cleaner cut on top but a fuzzy surface at the bottom.

It's worth noting that you should always use an upcut bit for plunging operations. When a downcut bit plunges straight down, the chips have nowhere to go but to grind against each other as the bit spins, which is going to create friction and start a fire.

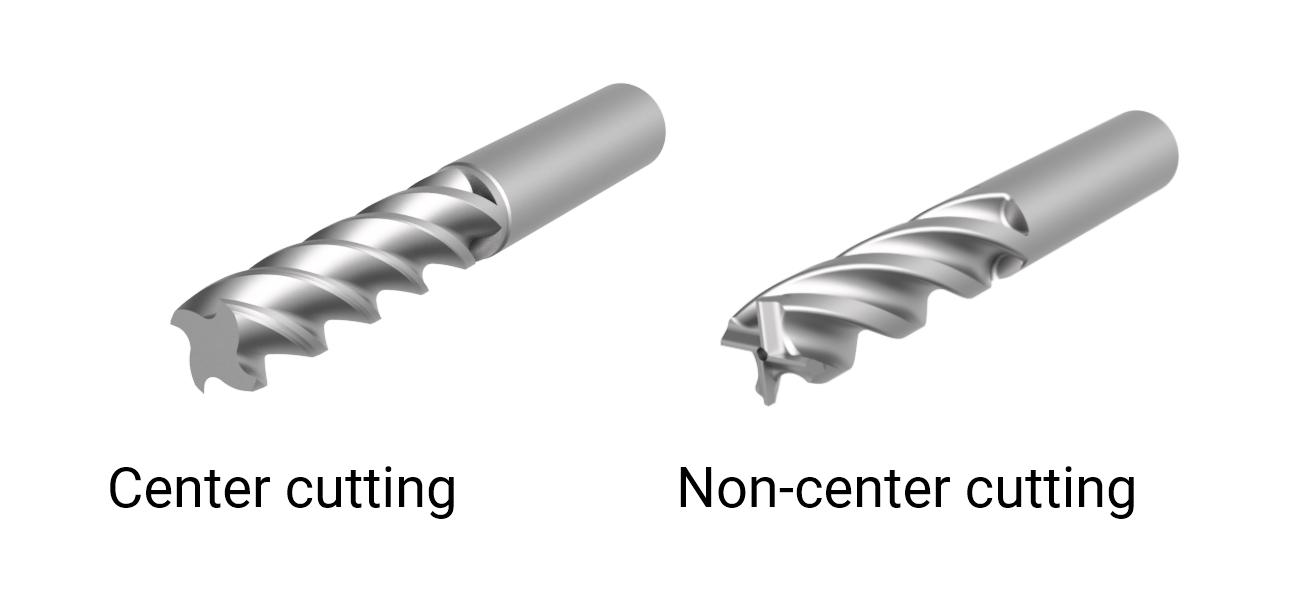

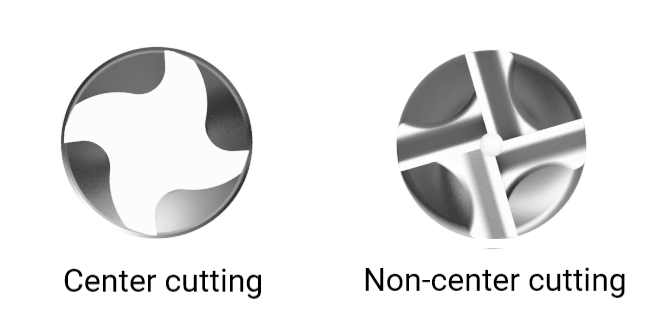

¶ Center Cutting vs. Non-center Cutting

Router bits are either center cutting or non-center cutting. The cutting edges of a center cutting bit go all the way into the center, whereas those of a non-center cutting bit leave a hole in the center. Center cutting bits can plunge straight down into the material, while non-center cutting bits cannot.

Non-center Cutting vs. Center Cutting

If a non-center bit were to plunge into the material, the material engaging with the hole in the cutting edges remains uncut, which can break the bit and lead to burning. To use these bits, you need to drill a pilot hole or use ramp plunge moves.

Non-center Cutting vs. Center Cutting

¶ Size

Basically, size determines what you can do with any given router bit. Large ones are good at cutting a lot of material, but it comes at the cost of details. Smaller bits provide higher resolution in detail, with a trade-off in strength and machining efficiency.

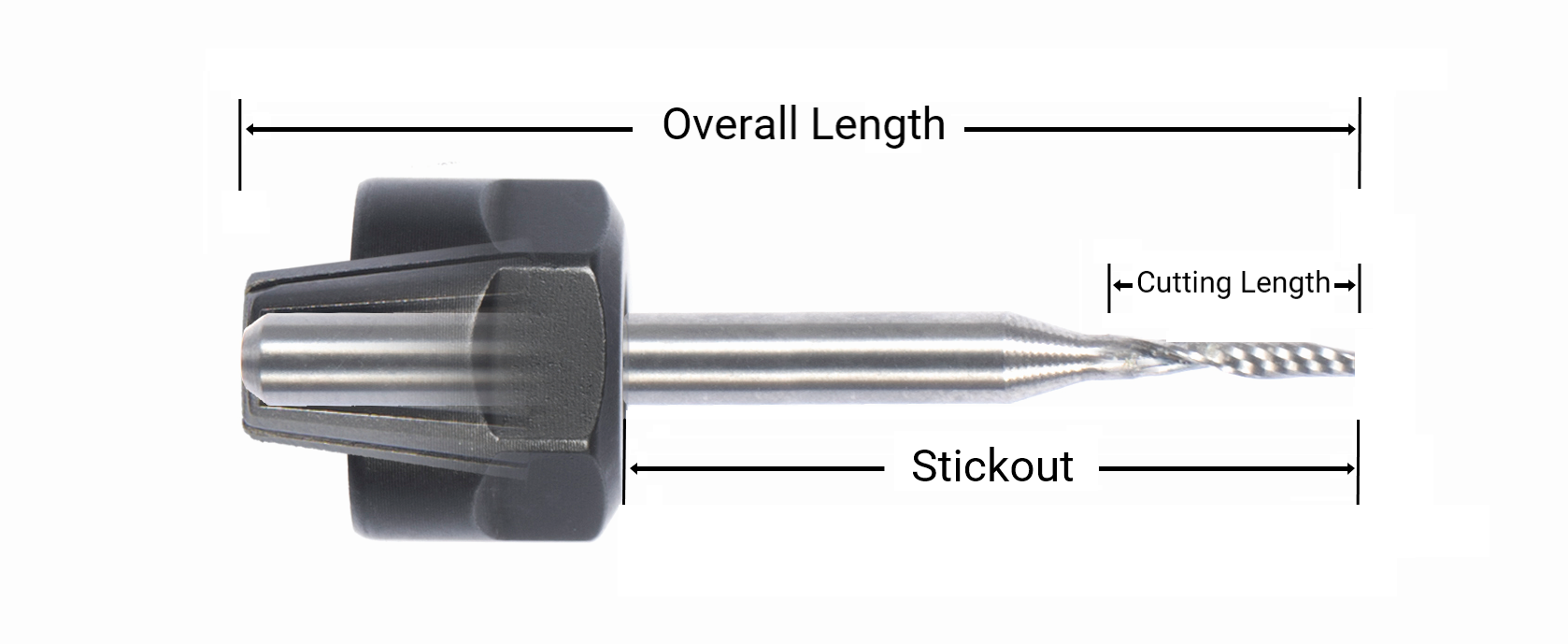

¶ Overall Length

The overall length is the distance between one end of a bit to the other. Longer bits are able to reach down deeper into the material. Now, you might believe that having longer bits sounds like a safe bet since they offer more choices. Unfortunately, that's not the case.

This brings us to a concept called "stickout". Stickout refers to the distance from the end of the collet (i.e., tool holder) to the bit's tip. It's this part of the bit that works without support. The more stickout, the less rigid a tool is. If it sticks out too far, the bit is prone to be bent by the cutting force.

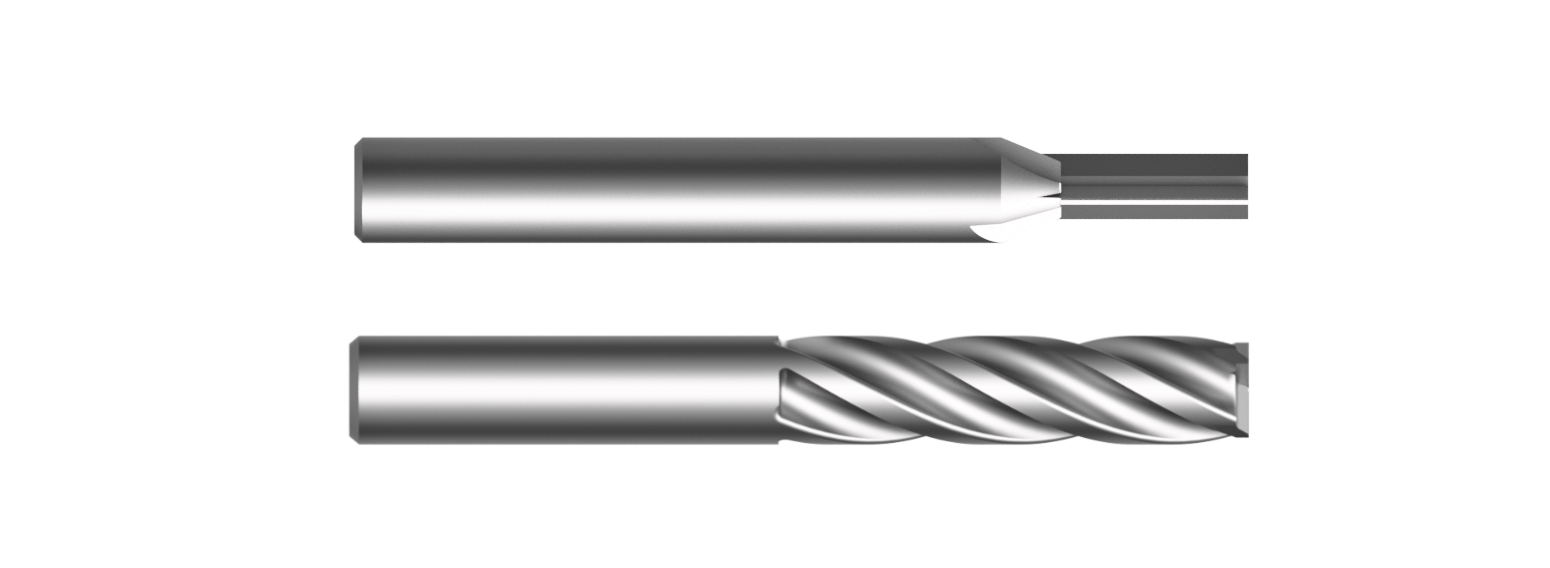

¶ Cutting Length

As we can see, cutting edges (or flutes) cover only a portion of the bit. The cutting length (also called "flute length") of a bit determines how deep it can cut into the material. Note that the cutting depth should never exceed the flute length of your bit. Otherwise, chips won't be pulled out properly, and your bit could be damaged by the heat accumulated.

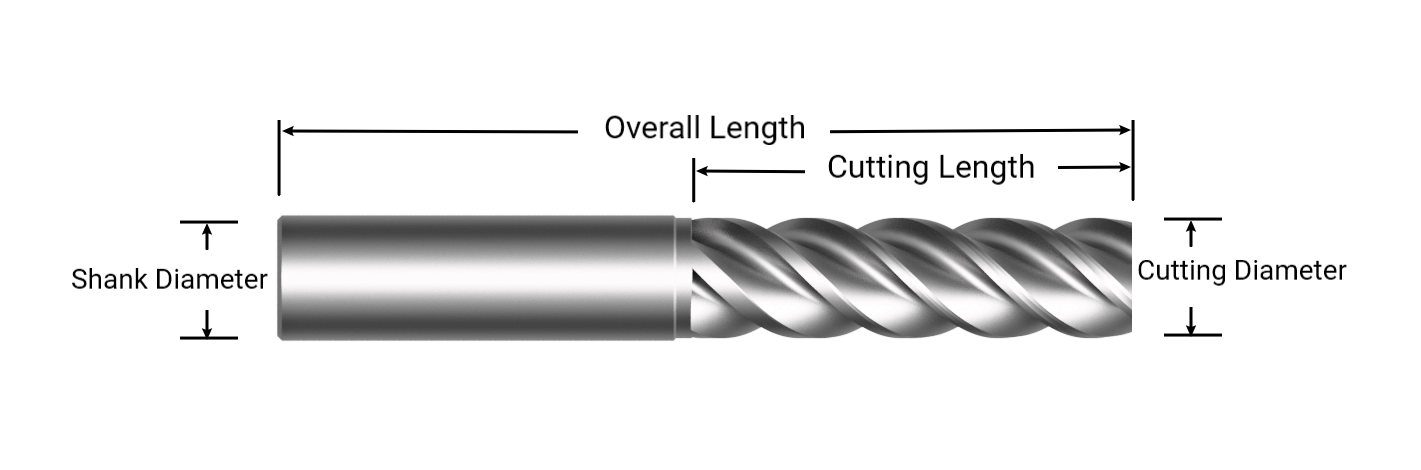

¶ Shank Diameter

The shank diameter is the width of the non-cutting end of the tool. This is the diameter that will go into your collet.

¶ Cutting Diameter

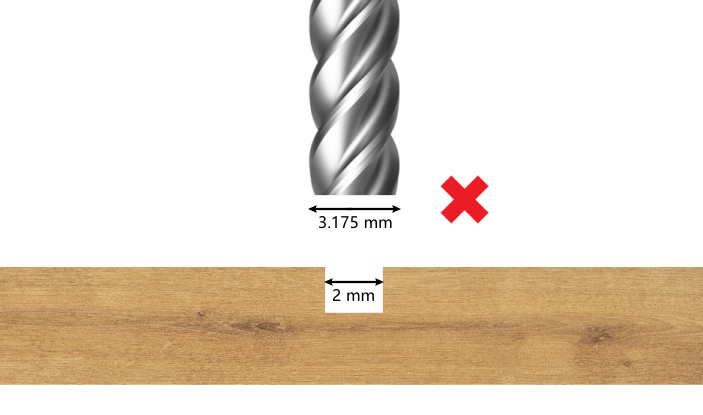

This is the diameter of the cutting end of your router bit. It is often the first thing to look for when choosing a tool for your job, as it determines the resolution of cutting.

When cutting, the cutting edge will leave a circular profile in every internal corner, with a radius equal to half its diameter. Also, it is impossible to cut out features that are smaller than the cutting diameter because bits are cylinders (except for V-bits).

On the other hand, a bigger cutting diameter makes your bit more rigid, allowing deeper cuts. Besides, bits with a larger cutter diameter can remove more material per unit of time, which means you can do the same job faster.

¶ Common Router Bits

There are literally tens of thousands of tool types and variations available for CNC machines.

Milling bits, including end mills, face mills, and v-bits, are designed to cut with their cutting edges as they move laterally through the material. By contrast, drill bits are intended to be used for drilling holes, plunging straight down into the material.

¶ End Mill

End mills are designed to cut with their cutting edges on the circumference of the bit, but they do have cutting edges on the end surface too. Though center-cutting end mills are capable of plunging straight down, such operations could be demanding for them and should be avoided if possible.

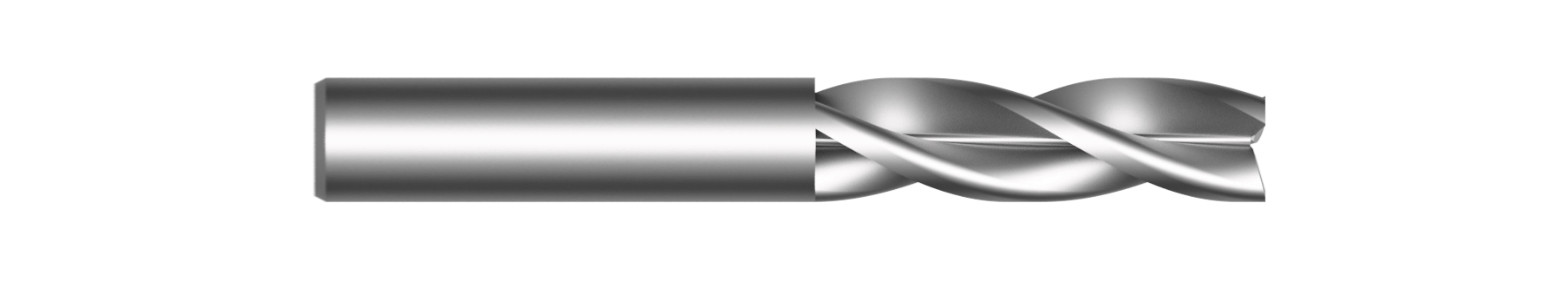

¶ Flat End Mill

With a nearly 90-degree angle between its circumference and end surface, a flat end mill is going to create neat square corners at the bottom and a flat surface anywhere it passes over the top of. They are great for removing large amounts of material, widely used for everything from roughing to cutting pockets and 2D contours.

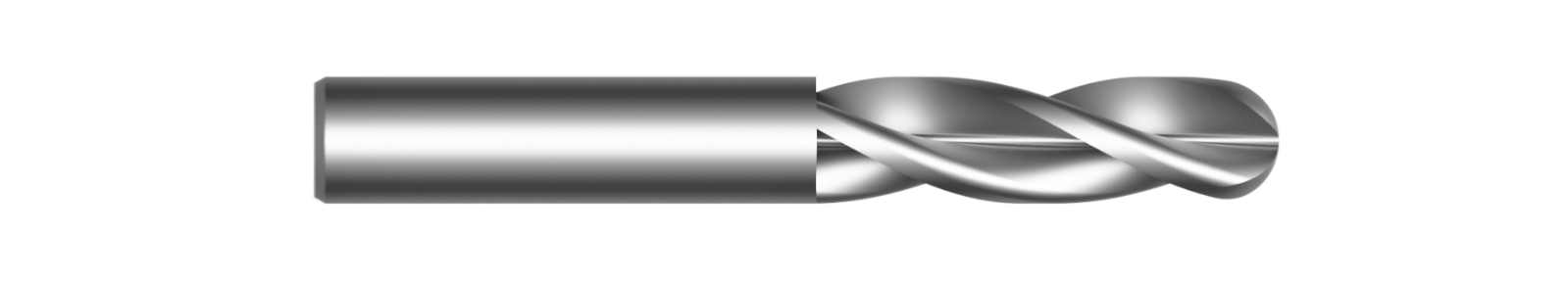

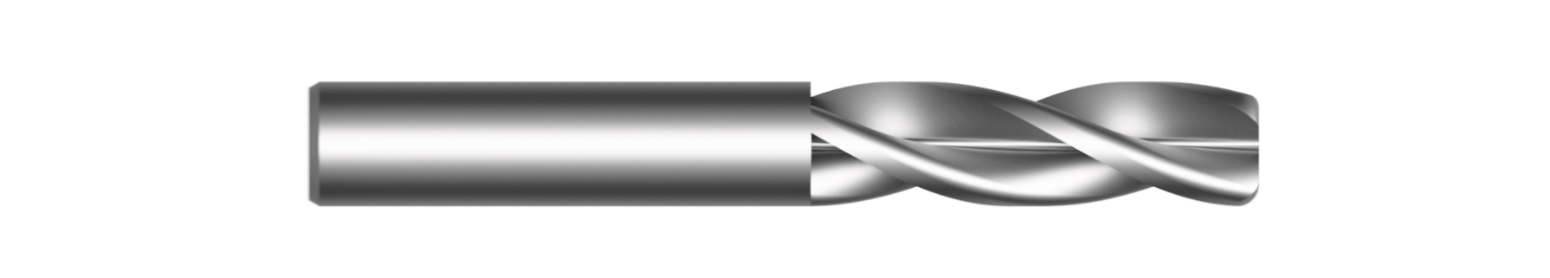

¶ Ball-nose End Mill

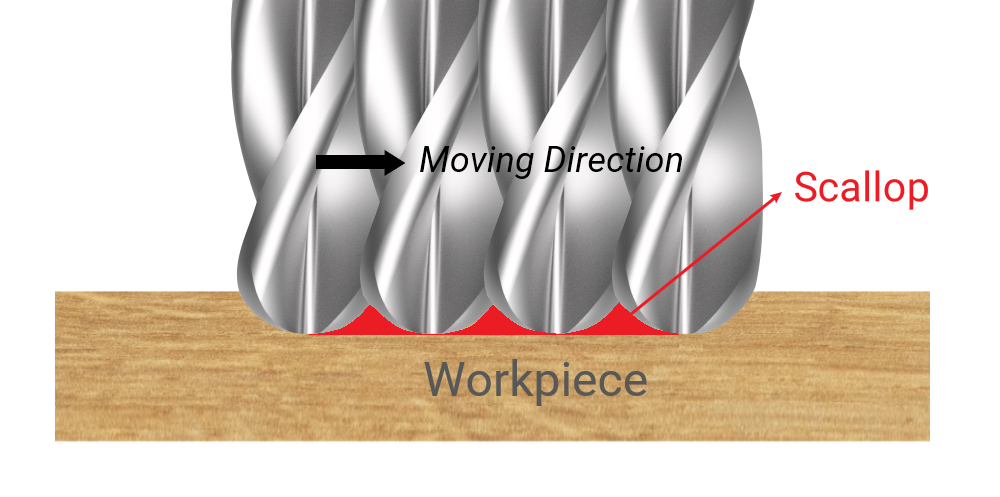

The circumference and the end surface of a ball-nose end mill form a rounded corner. The radius of that round corner equals the cutting radius (i.e., half of the cutting diameter). These mills excel at creating curvature or detail-rich 3D shapes like relief.

Since their tips are round, cutting out a perfectly flat surface is challenging for these bits because they will leave scallops on the workpiece.

¶ Bull-nose End Mill

You can see bull-nose end mills as a transition between flat and ball-nose ones. The radius of its round corner is smaller than the cutting radius. Since they combine a flat bottom with round corners, they can create flat-bottomed pockets with rounded corners at once without changing tools.

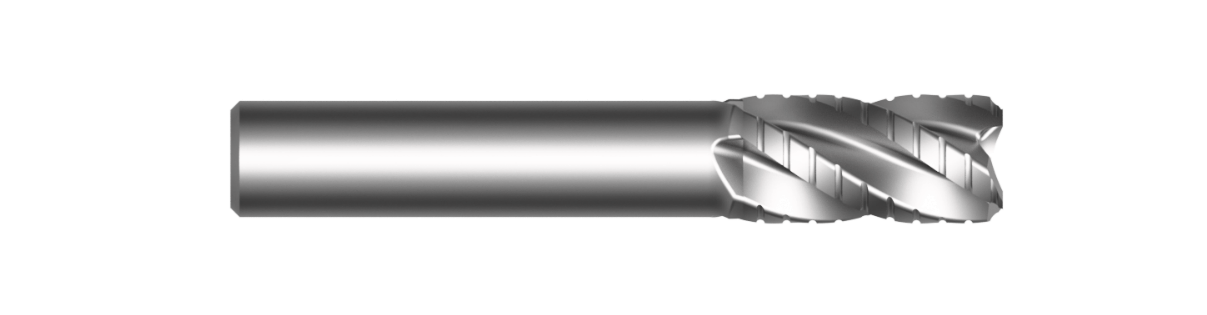

¶ Roughing End Mill

Roughing end mills have many serrations on the cutting edges to quickly break up chips, which is great for efficiently removing a large amount of material. The thing with roughing end mills is that they will leave a poor surface finish. Roughing end mills are for roughing only.

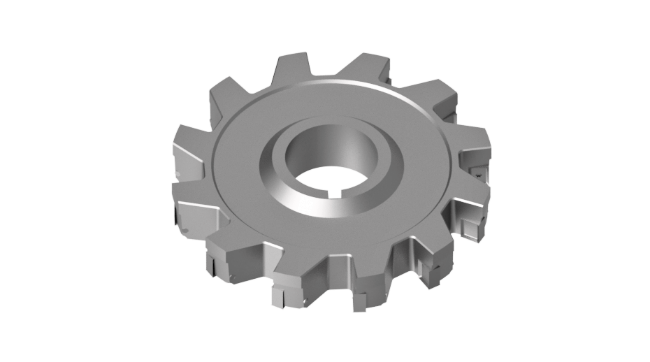

¶ Face Mill

Face mills are designed to cut with their cutting edges on the end surface of the bit. They often come with multiple cutting edges that are replaceable, which allows removing more materials at higher speeds. These mills are mostly used for creating a large and smooth flat face.

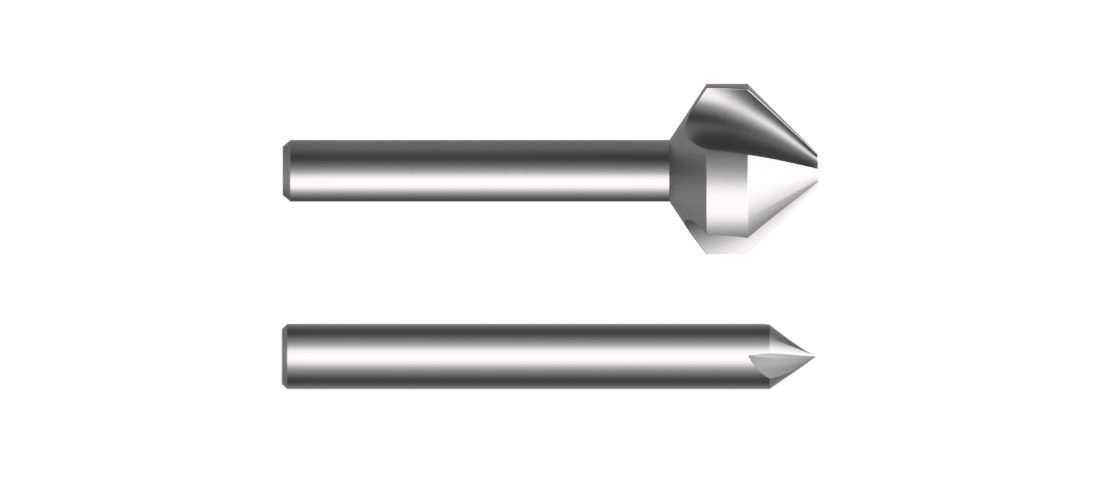

¶ V-bit

V-bit, also known as chamfer mills, are used for chamfering, deburring edges, and letter engraving. They are not so good at cutting profiles or carving out pockets since they'll leave a sloped surface on the workpiece.

V-bits are available in many sizes and angles, although 90, 60, and 30 degrees are most common. A smaller angle often comes with a smaller cutting diameter, supporting shallower cuts while retaining more details. A bigger angle allows wider cutting diameter and deeper cuts.

¶ Drill Bit

Drill bits are designed to bore straight down into the material with their pointed tip. Unlike milling bits, their flutes only function as the passage for chips to be pulled out. They are often used for pre-drilling holes for screws.